Contribution to the global environment

Promoting CO2 emissions reductions across the entire value chain to achieve carbon neutrality

Material issues relating to the global environment Contribute to a decarbonized society through actions that lead by example and advanced technological innovations

Vision for 2030

- Reduce Scope 1 and 2 emissions by 80% and Scope 3 emissions by 25% by 2030 (SBTi-certified target)

- Achieve carbon neutrality across the entire value chain (Scope 1, 2, and 3) by 2050

- Develop and supply products with low environmental impact using advanced technologies

Action

Reducing Scope 1 and 2

In anticipation of the future introduction of carbon pricing, we are promoting CO2 emissions reduction from both cost competitiveness and risk management perspectives, aiming to reduce environmental impact in business activities.

We are implementing a number of initiatives to reduce CO2 emissions at all our business sites, including energy-saving activities and streamlining manufacturing processes.

We are striving to reduce CO2 emissions by purchasing electricity generated from natural energy sources, such as solar, hydroelectric and wind power (also known as green power), and installing solar power generation systems.

Development of a compact, lightweight, and efficient direct-drive system for in-wheel EVs using a new air-cooled structure

Astemo has developed a 12-inch air-cooled direct-drive system for compact vehicles such as Kei cars. By directly transferring the driving force of the built-in motor to the wheels and employing a simple air-cooling system, the system achieves compactness, light weight, and high efficiency, and delivers a continuous rating of 5.5 kW. This product will join our existing 16 and 19-inch lineup and is targeted for implementation around 2030.

The newly developed 12-inch model improves heat dissipation performance with a “rotary fin-structure” having heat-dissipation fins arranged on the entire outer surface of the motor. It achieves a continuous rating of 5.5kW per wheel and a maximum output of 13kW, providing the drive performance requirements of Kei car EVs in a four-wheel configuration.

This structure—which was developed in collaboration with Hitachi, Ltd.’s Research & Development Group—is simplified compared to oil-cooled systems, helping to eliminate issues such as layout complexity and increased costs. In addition, this system uses “easy disassembly concentrated coils,” which were developed through Green Innovation Fund Projects / Next-Generation Motor Development (JPNP21026) commissioned by NEDO. Achieving higher motor efficiency and designed to be recyclable, these coils have a high space factor and are easy to disassemble. We have also deployed this technology across our 16- and 19-inch models, allowing for broad applicability in various EVs.

12-inch air-cooled direct-drive system

Material issues relating to the global environment Contribute to a sustainable recycling-oriented society and a society harmonized with nature

Vision for 2030

- Utilize sustainable materials (recycled and environmentally friendly materials) and supply products with maximized circular design

- Effectively utilize waste and water resources

Action

Effective use of resources

To advance effective use of resources and waste reduction, the Astemo Group has set medium-term targets for FY2030 of reducing waste generated by 9.0% compared to FY2021 and achieving a waste effective utilization rate of 90.0%.

As part of these efforts, we recycle some alternators and starters collected from car dealerships at our own plants and reship them as rebuilt products. We also promote effective resource use by recycling scrap metal and other by-products generated during the manufacturing process. As a result of these initiatives, we achieved an 8.1% reduction in total waste generated in FY2024 (compared to FY2021).

Recycled materials collected at a plant in the Miyagi area

Initiatives with the government and the industry association to utilize recycled plastic materials

As a member of the Japan Auto Parts Industries Association (JAPIA), Astemo participates in the activities of the Circular Economy Task Force Pilot Study Team, established by JAPIA to promote the realization of a recycling-oriented society.

As one of these activities, we cooperated in a waste plastic collection event organized by Sendai City and analyzed the material properties and identified issues concerning recycled materials made from waste plastic products provided by citizens. Going forward, based on these results, we will support the formulation of action plans and the development of systems by government agencies, with the aim of applying recycled plastic materials to automobiles.

Focusing on the development of plastic upcycling technology

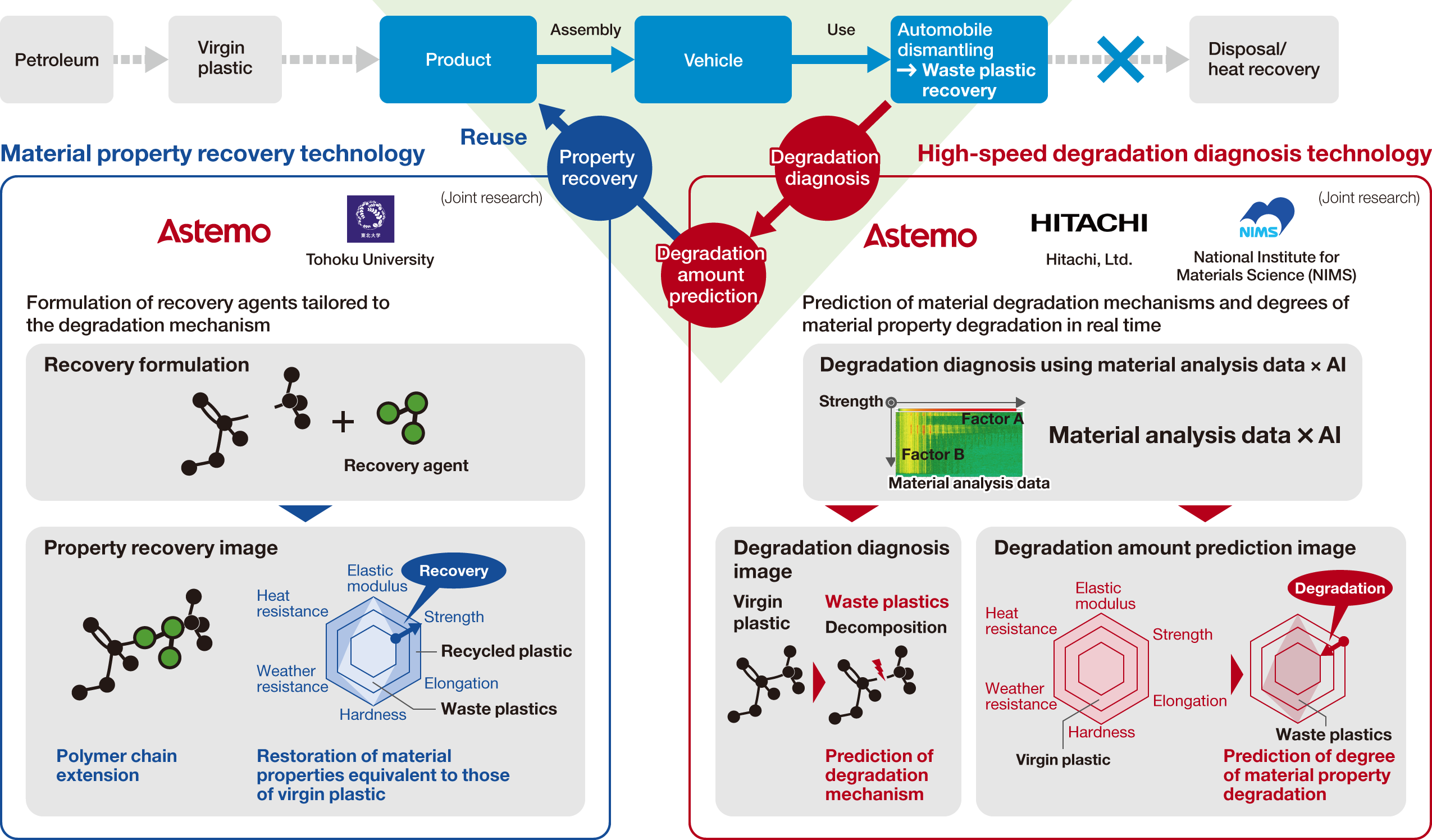

Astemo is working to establish plastic upcycling technology that reduces waste and promotes resource recycling by combining its proprietary “high-speed degradation diagnosis technology” researched in collaboration with Hitachi and the National Institute for Materials Science (NIMS), and “material property restoration technology.” researched in collaboration with Tohoku University.

In this initiative, we use chemical analysis data from recovered used plastics (waste plastics) to predict material degradation mechanisms and degrees of material property degradation in real time using AI. In addition, we are working on the development of technology (recovery formulations) for restoring the material properties of waste plastics to levels comparable to virgin plastic, making it reusable in products. Combining these two technologies makes it possible to reuse waste plastics that was previously difficult to reuse due to severe degradation. This not only reduces waste but also enables the reuse of plastic from various sources.

Furthermore, it produces a stable supply of recycled materials, leading to a significant reduction in CO2 emissions compared to producing new materials. Through this technology, we will build a recycling-oriented society and promote the use of recycled materials, contributing to the creation of a sustainable future.

Increasing the recycling rate of waste plastics through degradation diagnosis and property recovery

Waste Reduction Initiatives

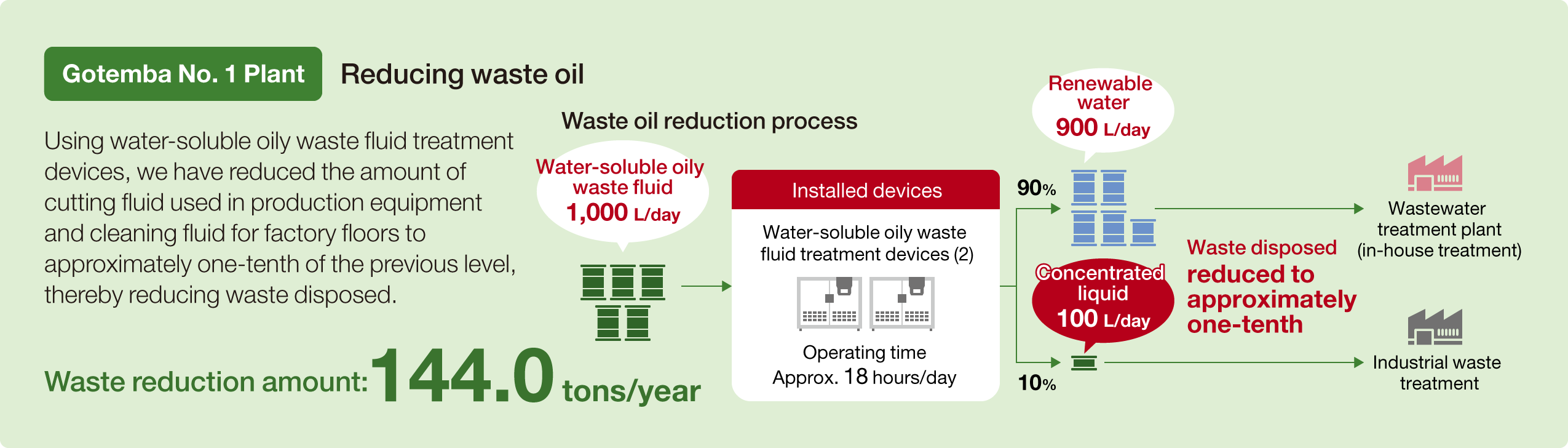

At the Gotemba No. 1 Plant, by using devices to treat water-soluble oily waste fluid, we have reduced the amount of cutting fluid used in production equipment and cleaning fluid for factory floors to approximately one-tenth of the previous level, thereby reducing the amount of waste disposed.

At the Akita Plant, the amount of waste disposed is reduced by compressing and solidifying the grinding and polishing sludge used in the grinding process to form briquettes, and the grinding fluid extracted through this compression is reused. As these briquettes are valuable waste, we then sell them, thus contributing to the effective use of resources.

Grinding and polishing sludge compression device

Briquettes after grinding and

polishing sludge compression

Effective use of water resources and water risk management

The Astemo Group regards the effective use of water resources and water risk management as key challenges in realizing a recycling-oriented society and is advancing systematic initiatives to address these challenges. We have set a long-term target for FY2030 of reducing water usage by 3.0% compared to FY2021. Each plant and business site regularly monitors water usage and wastewater discharge, maintaining ongoing oversight of actual environmental impact and progress toward reduction goals. As a result of these initiatives, we achieved a 3.2% reduction in total water usage in FY2024 (compared to FY2021).

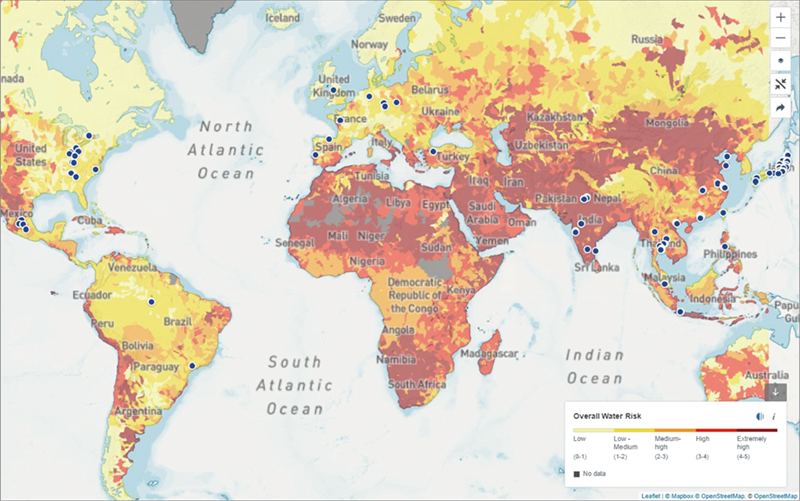

In our assessment of water risks, we used the international water risk assessment tool Aqueduct to identify regions where water scarcity is a concern. The assessment revealed that our sites in Mexico, China, Thailand, India, and Indonesia may face water risks, and we will therefore further optimize water resource use and enhance water risk management at these locations.

In addition, we are also implementing a comprehensive approach to water risk management, which includes addressing the potential impacts of natural disasters such as floods on our business operations.

Water risk assessment with Aqueduct